Industries

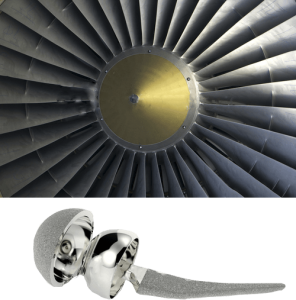

Different sectors of the precision investment casting industry place different requirements on the refractories used. Foundries making parts for turbines and medical applications demand much lower, potential contamination levels than in general commercial casting.

Similarly, refined precious metals place higher demands on the quality of their container than is allowable earlier in the production chain. Various types of crucible material are available to meet the preferences in terms of reaction, erosion and thermal shock.